What would just about any trucking company be unable to do without? Freight! Without the goods to haul, trucking companies would be unable to pay the bills. Yet, far too often truck drivers and fleet managers don’t have cargo securement at front of mind. It does not matter whether you operate light-, medium- or heavy-duty vehicles. Cargo securement should be a top priority.

Even more, fleet managers can focus on cargo securement without worrying to much about expenses. There are ways to reduce cargo damage, increase productivity, and enhance your return on investment without breaking the bank. All you must do is focus on cargo securement basics. Let’s take a closer look.

If you were to ask top cargo securement experts for their insights and advice on cargo securement, you might get varied answers. Fortunately, with proper due diligence, you and your truck drivers can have peace of mind that your cargo is safe and secure for transport. It all starts with training.

Implement a Proper Cargo Securement Training Program

The first thing any responsible fleet manager must do is ensure their truck drivers are equipped for success. Don’t let cargo securement become an afterthought to your truck drivers. Start with proper training to ensure your people take cargo securement seriously.

What should you consider? First, some common mistakes include:

- Not using the right number of securement devices.

- Failing to double check after a third party has secured your cargo.

- Not checking securement every 50 miles on the road.

- Failing to secure items that you may not consider to be cargo but are.

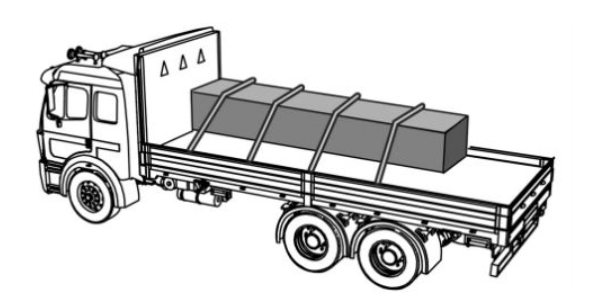

These are just a few examples of how truck drivers fail at proper cargo securement. No matter how many hours a driver has in the cab, they must be able to distinguish between different securement devices. Do you need chains or straps? Cargo nets or covers? Should you use corner protectors? Do you even need them? Have you completed a pre-trip inspection checklist and ensured everything was covered?

They say old habits die hard, so the key is to ensure your truck drivers are learning and keeping good habits from the start. To ensure good habits aren’t forgotten, you must build cargo securement into your overall safety culture. Have you considered a catchy slogan? Or perhaps providing some motivation in the form of safety incentives for cargo securement spot checks? Also consider the various tools you have at your disposal.

Utilizing Tools to Ensure Proper Cargo Securement

There are many tools out there at your disposal to ensure proper cargo securement. It is up to you to ensure you properly investigate them. The key is to ensure you have the right tools to make sure everything is secure. You should be well aware of items like:

- Straps

- Ties

- Tarps

- Winches

- Shelving

- Drawers

- Bins

- Doors

You may also want to consider technological solutions such as tie down calculators. Tie down calculators help truck drivers keep track of securement requirements, standards, and references. Armed with this information on their smartphone, cargo securement becomes as easy as “There’s an app for that!”

Composite bulkheads are also good options. These serve as barriers between the truck driver and the cargo area. Not only does it protect the cab and driver, but it also provides a customizable storage area and sound barrier. This is convenient when the driver needs to sleep, but also when they need to stay alert on the road with no distractions.

Cheapest is Not Always Better

Another best practice is to ensure you are not opting for the cheapest cargo securement option simply because it will save you some coin. Sure, simple devices that are easy to use and maintain may seem like an easy target to save a buck. But it may be beneficial to opt for a powered or remote-control system, which often pay for themselves in the long run. Truck drivers also appreciate it when you provide advanced systems to help them make their job easier.

Also make sure you don’t skimp when it comes to stocking your cargo securement supplies. Sure, it may save you some money to go with only what you think you need. But if you wind up hauling damaged or incorrect cargo securement devices simply because you tried to save a buck, you are going to have problems in the long run. Saving money now might be losing out later if you don’t conduct proper due diligence.

Make sure you conduct regular inspections of your cargo securement equipment. Much like you work hard to ensure a proper preventative maintenance program for your vehicles, you should also consider one for your cargo securement devices. You never know when that one strap might be too warn out to get the job done.

Focus on Safety

Trucking companies are under a lot of pressure to get the job done. As a result, it could be that they don’t pay enough attention to cargo securement. This could be especially important considering your type of operation. Commercial van users, for example, need to pay extra attention to payload and truck driver safety. But no matter your operation, safety should be key.

Consider what happens when your cargo is overweight or not properly secured. Overweight cargo discovered during an inspection can result in hefty fines. But even more than that, it could put your truck drivers in danger. Vans especially come with specific challenges.

Last-mile trucking operators must pay special attention due to the nature of their jobs. When it comes to operating in urban environments, you could find yourself stopping suddenly, running over bumps, making sharp turns, or even getting into accidents. Any one of these events or more could result in cargo shifting unexpectedly. If it is not properly secured, you could have a big problem on your hands.

This is especially true if you are hauling particularly heavy items. When an accident occurs, there are forces at work you cannot plan for. Even the most minor of evasive maneuvers can result in major shifting in your cargo hold. The last thing you want is cargo shifting in an unpredictable or unsafe manner.

Top Tips for Cargo Securement Safety

Trucking companies need to make sure cargo securement is in their DNA. They need to make it a critical and important part of their safety culture. Sure, pre- and post-trip checks are important. Everything a truck driver is called upon to do is important, but cargo securement should be at the top of that list.

Make sure all of your equipment locks, clicks, or snaps together as it should. Whether you are working with shelving, boxes, flooring, or overhead compartments, you need to make sure your freight is locked together as one cohesive unit. That way if something unexpected happens, your cargo responds as one cohesive unit, providing extra strength from the entire system.

Also make sure you do not overtighten, which is a common problem. Overtightening your cargo securement devices can quickly result in failure. Make sure your truck drivers are aware of the procedures necessary to prevent overtightening. Not only can overloading your cargo area cause safety problems, but it will also lower your truck drivers’ overall level of productivity.

New Solutions for Old Cargo Securement Problems

Sometimes you may want to consider new solutions to an age-old problem. If you run curtain-side vehicles, consider adaptive strap systems, which suspend from your trailer ceiling and make cargo placement and securement both faster and easier. Your truck drivers will thank you.

If you are considering upfitting your vehicles with new cargo securement devices, make sure you check to make sure your equipment is in proper working order before you make the upgrade. Remote power systems are a good bet to ensure your drivers stay focused.

In the end, make sure you follow your local rules carefully. Even if you run light- or medium-duty vehicles, they are subject to the same regulations as heavy haul vehicles. Make sure you pay close attention to airline tracks, logistics straps, and cargo nets.

Remember, when it comes to cargo securement, it is always better to be safe than sorry. You can never be too cautious. Make sure your tiedowns and other cargo securement devices meet FMCSA standards. Also set standard measurements for your technicians. They should be just as adept at isolating problems with cargo securement devices as they are at isolating problems with your vehicles. By focusing on proper cargo securement, you can ensure safety, driver satisfaction, and minimal violations.